Vacuum Heat Treatments

HS, Tool Steels, stainless steel, PH, Maraging, Ni and Co Superalloys..

The use of vacuum technologies with pressure gas quenching joined to control and management systems of parameters of heat treatment by software allows to ensure to the growing requests in quality terms of the materials after heat treatment. Among the advantages compared to the treatment made by traditional technologies there are: the possibility to obtain surfaces without oxidation and decarburization, the possibility to manage the cooling speed by the material, the geometry of the pieces and the mechanical characteristics required by quench pressure, cooling time and zones. The vacuum quenching is mainly used for HS and HSS, tools steels (for hot and cold working), for martensitic stainless steels and for powder metallurgical steels. The vacuum technologies is massively used for the solubilization of austenitic stainless steels treatment, precipitation hardeningand for the Ni and Co super-alloys.

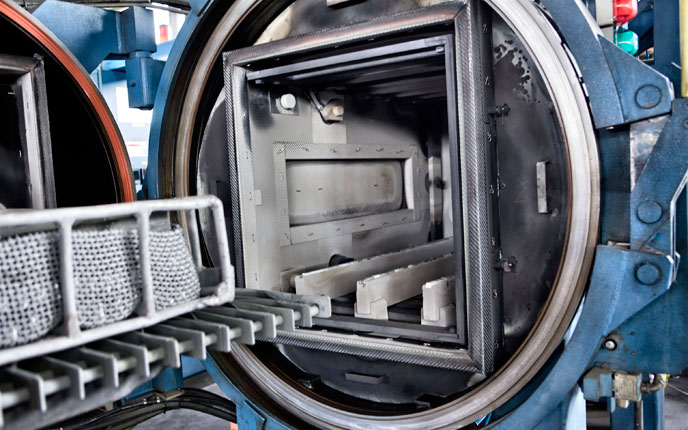

TAV fastjet type furnace

Max Dimension/Weight 500 x 500 x 1100 mm / 500 kg

Max Temperature 1250°C

Vacuum Pressure 0.01 mbar

Max Quenching Pressure 10 bar (N2)